Q:How steel plate correction work in a CNC cutting machine?

A:Operation of steel plate correction

Take the SteelTailor plasma CNC cutting machine as an example to demonstrate how to implement the steel plate correction.

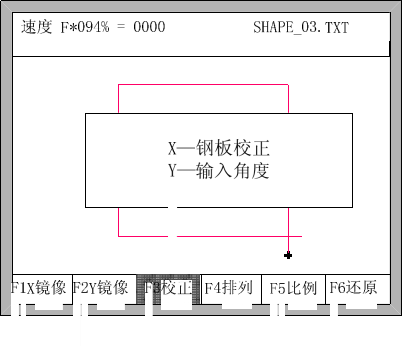

- After the cutting graph code is input into the numerical control system, if the system still does not operate, press [F4] (adjust) to enter the adjustment interface, and press [F3] (correction) to display the system prompt as shown in

Fig.1 Steel plate correction and input angleIn the interface, after [X] is pressed, the system will adjust the steel plate.

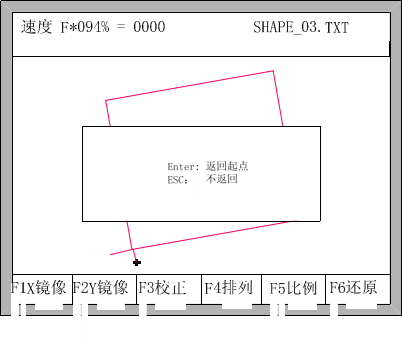

Fig.2 Steel plate correction

1) Location of the offset start point: manually move the torch of CNC cutting machine to the edge of either side or a corner of steel plate. After the cutting tip is aligned, press [X] to set the current point as the start point.

2) Location of the offset end point: Select the long side of steel plate where possible and move the cutting tip manually along this side. When the tip is moved again to the edge of this side, press [Y] to set the current point as the end point. (two points shall be far apart from each other and on the edge of steel plate)

3) Control system will automatically calculate the current offset angle of steel plate, and then automatically rotate and correct the graph.

4) After the completion of correction, the system prompts whether to return to the start point. If you press [ENTER], the system will return to the start point. If you press [ESC], the system will exit the correction and return to the graphical interface.

Fig.3 Return to the start point

In the interface, after [Y] is pressed, system will rotate the angle.

Fig.3.12 Rotate the angle

At this point, you can manually enter the angle, and press [Enter]. If the input angle is from -3600 to +3600, system will automatically rotate the graph according to the input angle.

Fig.4 Input the angle

- In this interface, press [Restore] to recover to the original graph.

Fig.5 Rotated angle

Steel plate correction and graph rotation

The steel plate correction of CNC cutting machine is actually based on the controller's graphical rotation function. So it may also be used for rotation of any angle according to the basically same operation.