This article is from SteelTailor blog:http://www.steeltailor.com/blog/whats-advantages-and-disadvantages-of-table-plasma-cutting-machine/

Table plasma cutting machine is widely used in automobiles, locomotives, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery, steel structures, ships and other industry area.

Plasma cutting machine working principle: CNC plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma.

There are two kinds of table plasma cutting machine:

One is traditional table plasma cutting machine. The plasma power is less than 100A. The cutting thickness is not more than 16mm.

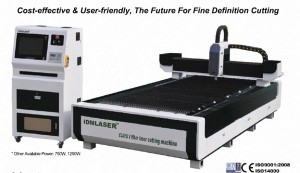

The other is high definition plasma cutting machine. High definition table plasma cutting machine cutting quality is better than traditional plasma cutting machine. The precision is high and good verticality section.

Advantages of table plasma cutting machine.

Table plasma cutting machine have advantages of 3—25mm metal plate. The plasma cutting speed is high. When cutting 3mm carbon steel sheet, the cutting speed is 10m/min. What’s more, the cutting quality is very good. The cutting surface is smooth, have small thermal deformation, almost no heat affected zone.

Compared with laser cutting machine, high definition plasma cutting machine is economical .

Disadvantages of table plasma cutting machine.

Table plasma cutting machine is not good at cutting sheet metal below 5mm.It may cause incision, slag surface and other issues.

Yeah!LegendB5II is an power table plasma cutting machine. It is an plasma cutting and marking machine. The plasma cutting thickness is 3mm-22mm.

More detailed information ,pls visit http://www.steeltailor.com/products/plasma-oxyfule-cutting/sheet_matel_plasma_cutting_machine/legendb5ii-table-cnc-plasma-cutting-machine.html