This article is from SteelTailor blog:http://www.steeltailor.com/blog/how-to-improve-cnc-laser-cutting-machine-cutting-precision/

CNC laser cutting machine is widely used in many area.How to improve CNC laser cutting machine cutting precision is one of the important question. Pls see following reasons.

- The material is one of the reason which affect CNC laser cutting machine cutting precision. Cutting stainless steel and aluminum will be very different precision.. Stainless steel cutting precision will be higher.

- The precision of cutting table. The precision of cutting table positioning determines CNC laser cutting machine repeat precision. Higher cutting table precision and higher cutting precistion.

- CNC laser cutting machine laser beam condensed into a cone. The laser beam is tapered down when cutting. If the thickness is larger, the precision will reduce.

- laser cutting machine generator laser coagulate big or small. If the laser beam focused on a small spot, the cutting precision is high .

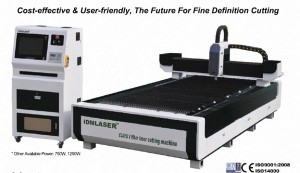

IDMLASER CLAYA V is an economical fiber laser cutting machine . More detailed information , pls visit:https://www.steeltailor.com/products/laser_cutting_and_engraving_machine/laser-cutting-marking-machine/clayav.html